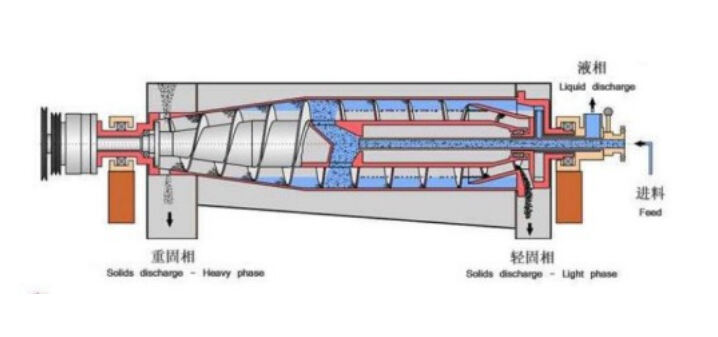

starch extraction centrifuge

The starch extraction centrifuge represents a pivotal advancement in starch processing technology, designed to efficiently separate starch from various plant materials through centrifugal force. This sophisticated equipment operates by utilizing high-speed rotation to create powerful centrifugal forces that effectively separate starch from other components based on density differences. The machine features a precision-engineered rotating drum with carefully calibrated perforations that allow for optimal separation while maintaining product quality. In industrial applications, these centrifuges can process large volumes of material continuously, making them essential in modern starch production facilities. The technology incorporates advanced control systems that monitor and adjust operational parameters to maintain consistent separation quality. Key features include adjustable rotation speeds, automated feeding systems, and precise moisture control mechanisms. The centrifuge's design also emphasizes energy efficiency and minimizes product loss during the extraction process. Applications extend across various industries, including food processing, paper manufacturing, and pharmaceutical production, where high-purity starch is essential. The equipment's versatility allows for processing different types of starch sources, from corn and potato to wheat and rice, while maintaining high extraction rates and product quality. Modern starch extraction centrifuges also incorporate safety features and easy-maintenance designs, ensuring reliable operation in demanding industrial environments.