Description of mud-water separation scheme of shield As an advanced excavation construction technology, shield tunneling plays an important role in tunnel engineering with its fully mechanized characteristics. In this method, the shield machine is us...

Description of mud-water separation scheme of shield

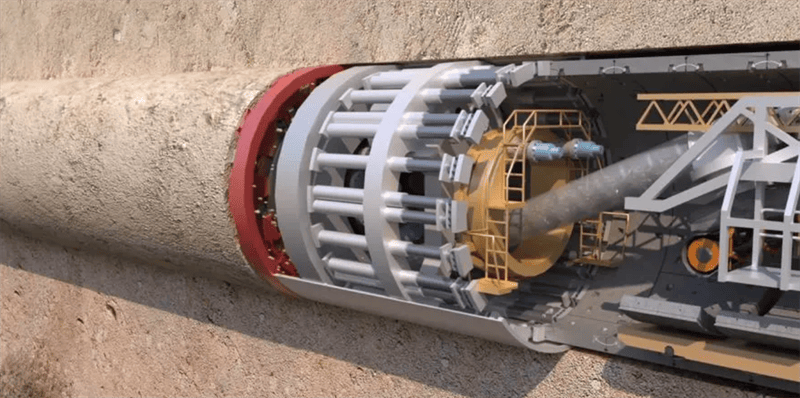

As an advanced excavation construction technology, shield tunneling plays an important role in tunnel engineering with its fully mechanized characteristics. In this method, the shield machine is used to advance underground, and the surrounding rock is supported by the shield shell and prefabricated segments, which can effectively prevent the tunnel collapse. During the construction process, the cutting device excavates the soil in front, the excavating machine transports the muck to the surface, and at the same time, the concrete segments are pushed and assembled by hydraulic jacks to form the complete tunnel structure.

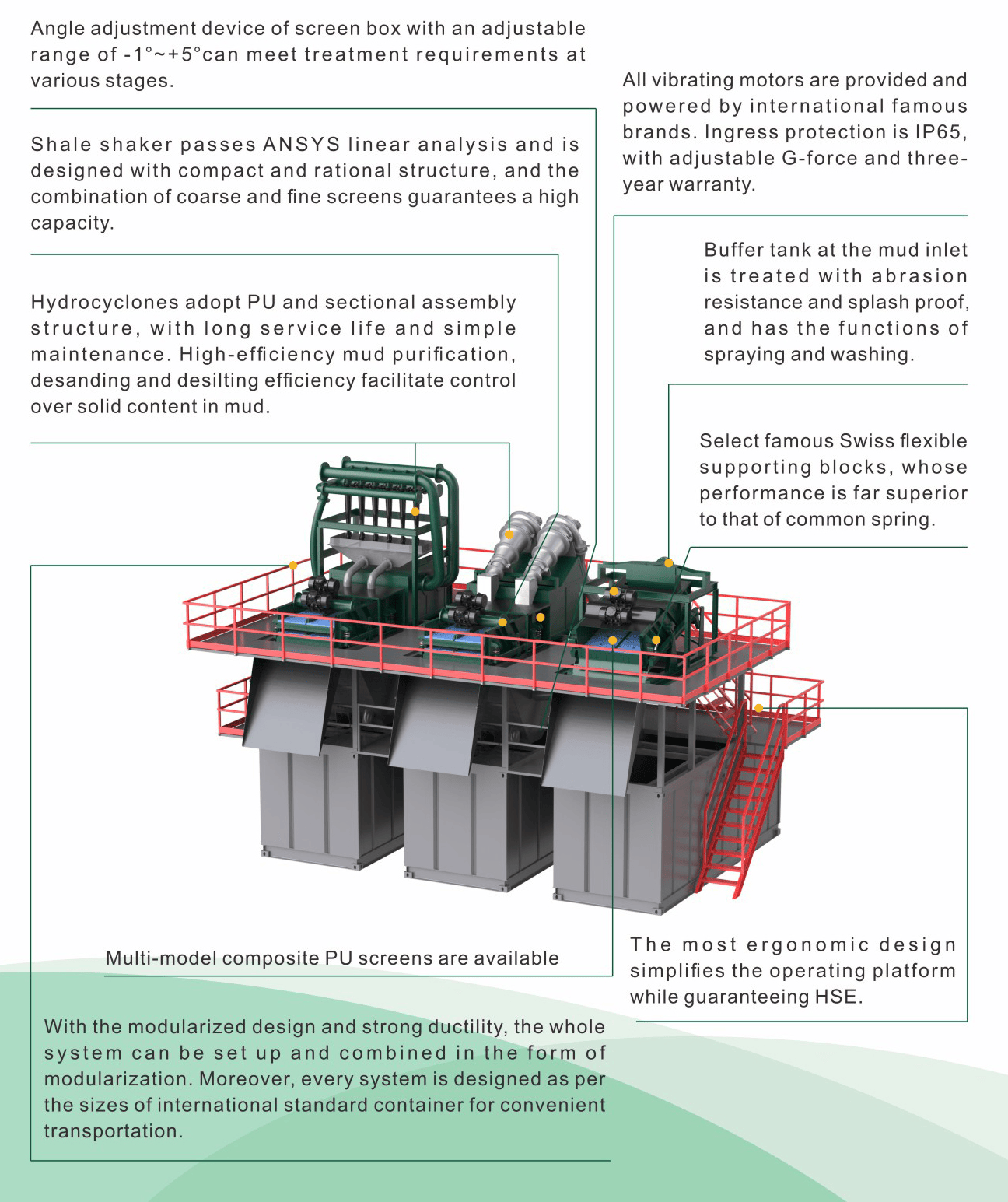

In shield construction, the Black Rhino mud-water separation system has become the industry benchmark for its outstanding performance, and the system consists of four core components: vibrating screen, sand cyclone, sand pump and cone tank. Among them, the vibrating screen adopts a double-layer screen design, the thick screen can effectively remove the large particles of slag in the mud, and the sand cyclone and the fine number of screens work together to remove more fine sand particles. The system adopts the mud closed-circuit purification process, which not only realizes the lower water content of slag, but also significantly reduces the impact of construction on the environment. In addition, the system is made of anti-corrosion and wear-resistant materials to ensure long-term stable operation of the equipment under harsh conditions.

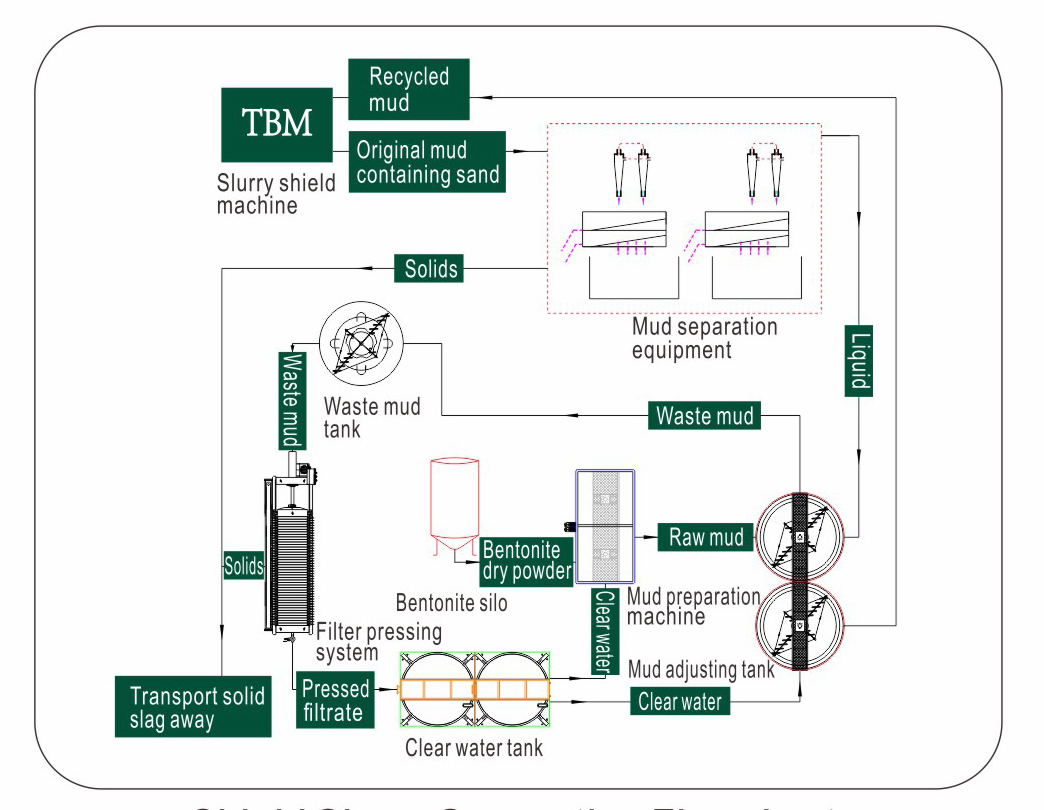

Slurry water separation process of shield

The advantages of Black Rhino's mud-water separation system

● Modular design, in line with container size, foldable operating platform makes the equipment compact, adapt to different site needs.

● Scientific process design, by adjusting the parameters of the vibrating screen (exciting force, inclination Angle, screen size), quickly adapt to various construction conditions.

● The use of advanced wear-resistant materials, especially composite wear-resistant pipes, significantly extend the life of the equipment.

● The process can be customized according to the characteristics of the material, and the processing capacity can reach 50-500 cubic meters/hour.

● Suitable for a variety of power systems, optional generator set, suitable for remote or unstable power areas.

● Support skid mounted or vehicle-mounted mobile design to meet the needs of different construction scenarios.

The Black Rhino KD Series Shield Slurry Treatment System is an efficient slurry purification equipment specifically tailored for slurry balance shield construction scenarios. The core system is integrated from four major components: vibrating screen, desanding cyclone, gravel pump, and conical tank. The system features a double-layer screen design vibrating screen, where the coarse screen can precisely intercept large particle slag in the slurry. Combined with the desanding cyclone and fine-mesh screen, it achieves efficient removal of smaller particle sand, comprehensively ensuring slurry purification effectiveness. Adopting a closed-loop slurry circulation purification method, it significantly reduces the moisture content of slag, reducing construction environmental pollution from the source and aligning with green construction requirements. All equipment accessories in the system are made of corrosion-resistant and wear-resistant materials, featuring ultra-long service life and ultra-low failure rates. It can easily adapt to various harsh working conditions in shield construction, providing stable and reliable slurry treatment support for the construction process.

Overall Advantages

Convenient Operation & Maintenance: The treatment process has been proven in practice to be simple and practical, streamlining the entire installation, operation, and maintenance process to reduce labor operation costs and technical barriers.

Flexible & Efficient Adaptation: Adopts modular integrated design, strictly planned according to standard container dimensions for easy transportation and installation. Equipped with a foldable operating platform, the structure is compact with small footprint. It can be flexibly placed according to the construction site, adapting to different shield construction scenario requirements.

Strong Adaptive Regulation Capability: By flexibly adjusting the vibrating screen excitation force, screen box inclination angle, and screen aperture size, the system can quickly adapt to different slurry characteristics, ensuring stable and up-to-standard purification effects.

Significantly Improved Durability: Slurry system pipelines are customized with composite wear-resistant materials, effectively extending pipeline service life, reducing equipment loss and replacement costs, and improving overall operational efficiency.

Wide Range of Customization: Treatment processes can be customized according to the material D50 separation point to precisely meet the separation requirements of different shield construction projects. Processing capacity covers 50–500 m³/h, adapting to diverse needs from small to large shield projects.

Flexible Power Supply Mode: Can adapt to different electrical systems according to on-site power supply conditions. For special scenarios, it can also be equipped with a self-contained generator set to ensure continuous and uninterrupted construction.

Significant Mobility Advantage: The entire system adopts a skid-mounted design and can be customized as an integrated vehicle-mounted mobile treatment unit, facilitating rapid relocation and deployment to improve construction convenience.

System Parameters

| Model | Processing Capacity | Separation Granularity | Total Installed Power | Total Weight | Overall Dimensions (L × W × H) |

| KD-50 | 50 m³/h | 40 μm | 21.98 KW | 2.1 t | 3 m × 1.8 m × 2.5 m |

| KD-100 | 100 m³/h | 45 μm | 25.44 KW | 2.8 t | 3.5 m × 1.6 m × 2.5 m |

| KD-200 | 200 m³/h | 60 μm | 48.44 KW | 3.6 t | 3.5 m × 1.6 m × 2.5 m |

| KD-500 | 500 m³/h | 60 μm | 192.44 KW | 18 t | 6.9 m × 2.2 m × 6.0 m |

| KDS-500 | 500 m³/h | 20 μm - 60 μm | 288.04 KW | 32 t | 8.1 m × 8.5 m × 8.2 m |

Application Areas

This system is specifically optimized for shield construction scenarios and can be expanded to various underground engineering slurry treatment scenarios. The core application areas include:

Slurry Balance Shield Engineering: As the core slurry purification equipment, it adapts to shield tunnel construction of different scales, such as urban subway tunnels, river-crossing tunnels, highway and railway tunnels, etc. It efficiently treats construction slurry, ensures safe and stable operation of tunneling equipment, and improves construction efficiency and project quality.

Underground Diaphragm Wall Construction: Treats slurry generated during construction, precisely controls slurry performance indicators, enhances trench wall stability and hole quality, providing assurance for the smooth implementation of underground diaphragm wall projects.

Pipe Jacking Construction Engineering: Efficiently separates and purifies sand-containing slurry generated in pipe jacking construction, realizing slurry recycling, reducing construction wastewater discharge and material consumption, and adapting to pipe jacking operation scenarios such as municipal pipeline network installation.

Bored Pile Foundation Engineering: Applicable to slurry treatment in bored pile foundation construction for bridges and high-rise buildings, removing solid particles from slurry, maintaining stable slurry performance, and ensuring hole quality and construction safety.

Cross-regional Shield Projects: With flexible transportation and deployment capabilities and the ability to adapt to different electrical systems, it can be sold overseas and to various domestic regions, adapting to shield engineering projects under different geological conditions and construction standards, providing professional slurry treatment solutions for cross-regional infrastructure construction.

The Black Rhino mud-water separation system not only improves the efficiency of shield construction, but also provides strong technical support for modern tunnel construction through its environmentally friendly design and reliable performance. Its modular design and flexible configuration make it able to adapt to various complex geological conditions and construction environment, and become an indispensable important equipment in shield construction.