HDD Mud Recovery System Description: The Horizontal Directional Crossing (HDD) mud recovery system is a mud treatment device specifically designed for horizontal directional drilling operations to enable efficient mud recovery and recycling while red...

HDD Mud Recovery System Description:

The Horizontal Directional Crossing (HDD) mud recovery system is a mud treatment device specifically designed for horizontal directional drilling operations to enable efficient mud recovery and recycling while reducing environmental impact.

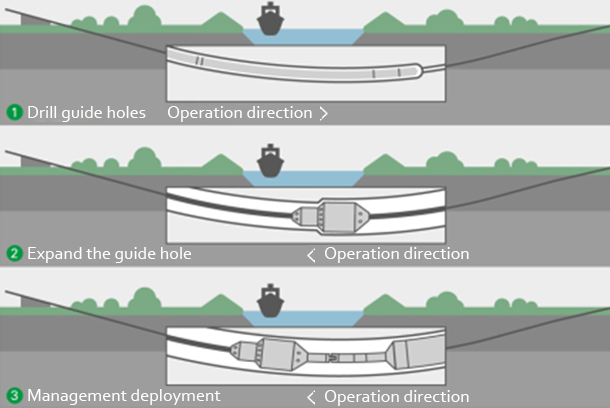

Horizontal Directional Drilling (HDD) technology has become a perfect construction method. It is used to lay pipelines for oil, natural gas, tap water, sewage and other fluids across rivers and canals, streets, highways, railways, airport runways, beaches, islands, crowded places with buildings, pipeline channels and canals, and to lay conduits for power and telecommunication cables. In recent years, the horizontal directional drilling technology has shown advantages in environmental protection and municipal pipeline network expansion projects and large-scale pipeline crossing river projects. The combination of mud recycling system and horizontal directional drilling rig matching construction completes the construction of pipeline crossing.

HDD horizontal directional drilling mud requirements

In horizontal directional drilling (HDD) construction, mud (drilling fluid) plays a vital role, directly affecting drilling efficiency, hole wall stability and drill lubrication. The following are the main performance requirements of HDD mud:

Basic performance requirements:

●Carrying drill cuttings: The mud must have good suspension ability to ensure that the drill cuttings are effectively carried out of the borehole.

●Lubricating drill tools: Reduce the friction between the drill rod and the hole wall, reduce torque and drag.

●Stabilize the hole wall: Prevent hole collapse and diameter reduction, especially in loose formations or aquifers.

●Cooling the drill bit: Reduce the temperature of the drill bit and extend its service life.

●Controlling formation pressure: Balance formation pressure to prevent water inrush or leakage.

|

|

HDD mud recovery system main equipment:

● Shale shaker: used to separate drilling cuttings and solid particles in the mud.

● Desander: remove the sand in the mud and improve the cleanliness of the mud.

● Desilter: further separation of fine solid particles.

● Centrifuge: used for processing high-density mud and separating ultrafine particles.

● Mud mixing tank: used for mixing and storing mud.

● Mud pump: Transport mud to each processing unit.

● Manifold system: Connect the equipment to ensure smooth mud flow.

HDD Mud Recovery System Configuration Parameters

Model |

KSMR-200 |

KSMR-350 |

KSMR-500B |

KSMR-500G |

KSMR-1000 |

Purification capacity |

50m³/h |

80m³/h |

120m³/h |

120m³/h |

240m³/h |

|

200GPM |

350GPM |

500GPM |

500GPM |

1000GPM |

Processing level |

Level 2 |

Level 2 |

Level 2 |

Level 3 |

Level 3 |

Processing accuracy |

20um |

20um |

20um |

20um |

20um |

HDD Drilling Rig Pull (T) |

≤86 |

80-107 |

100-300 |

100-300 |

350-800 |

Total Power |

33KW |

48KW |

85KW |

126KW |

184KW |

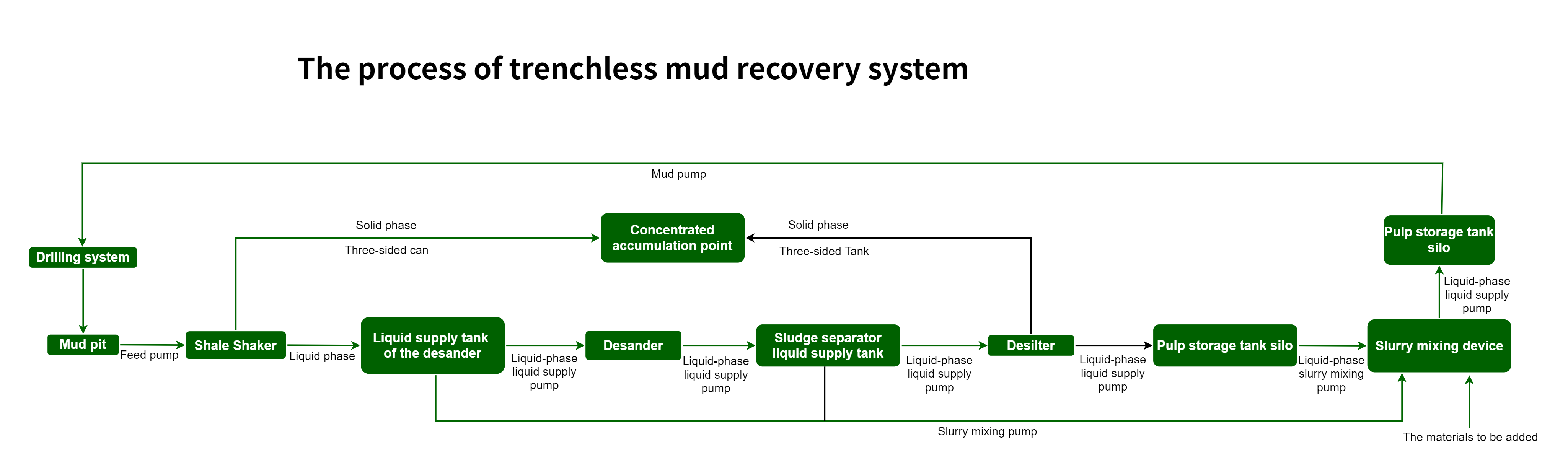

HDD Mud Recovery System process flow:

The liquid supply pump transports the mud in the mud pool to the recording tank of the shale shaker. After being processed by the shale shaker, the larger drill cuttings are separated and the treated mud flows back to the below desander liquid supply tank. The desander pump then transports the mud in the desander liquid supply tank to the desander cyclone. The mud treated by the desander cyclone overflows into the desander liquid supply tank. Then the desander pump transports the mud in the desander liquid supply tank to the desander cyclone. The mud processed by the desander cyclone overflows into the slurry storage tank and is pumped into the horizontal directional crossing system by the drilling mud pump for repeated use: In order to change the mud density, viscosity and other parameters to meet the mud performance requirements, the required mud materials are added through the slurry mixing device, and after being mixed evenly to meet the use requirements, they are pumped into the horizontal directional crossing system by the mud pump for repeated use.

Benefits of HDD Mud Recovery System:

Benefits of HDD Mud Recovery System:

● Efficient purification: The three-stage purification process ensures that the solid particles in the mud are completely separated, and the purification effect is remarkable.

● Energy saving and environmental protection: mud recycling reduces the use of new materials, reduces construction costs, and reduces waste emissions, meeting environmental requirements.

● Convenient operation: reasonable system design, simple operation, easy maintenance, suitable for long-term continuous operation.

HDD Mud Recovery System application field

Oil and gas pipeline laying: used for horizontal directional drilling of long distance oil and gas pipelines.

Municipal engineering: suitable for laying urban underground pipelines (such as water pipes, cables).

River crossing: for rivers, lakes and other waters of the pipeline crossing project.

Complex geology: adapt to sand, clay and other complex geological conditions.

Through efficient mud treatment and recycling, Black Rhino mud recycling purification system provides economic and environmentally friendly solutions for construction projects, helps improve construction efficiency and optimize costs, provides customers with one-stop services from design, manufacturing to construction support, and helps customers efficiently complete all kinds of trenchless construction projects.

The Black Rhino KSMR Series Trenchless Mud System is an integrated mud treatment equipment specifically developed for horizontal directional drilling (HDD) and other trenchless technologies. Its core applications are mainly reflected in the following three key dimensions:

Deep Mud Purification

Adopting a multi-stage solid control process, it successively performs pre-treatment through vibrating screens, secondary separation through desanders, and deep purification through desilters. It can precisely separate solid particles with diameters in the 15–44 μm range from the mud, effectively removing drill cuttings and other impurities, restoring the original stable performance of the mud, and ensuring the mud remains in good condition throughout the construction process.

Recycling & Reuse

The purified mud passes through a mixing device for material replenishment and uniform stirring, then is pumped back into the drilling system for cyclic use. The system’s mud recovery rate can reach over 90%, significantly reducing consumption of fresh mud and lowering material costs during construction.

Construction Guarantee & Environmental Compliance

Stable mud performance plays a vital role in construction, enabling functions such as drilling cooling, tool lubrication, and borehole wall protection against collapse, ensuring smooth construction operations. Simultaneously, it reduces discharge of waste mud, lowers environmental treatment pressure, and fully complies with relevant green construction requirements.

Features & Advantages

Relying on KOSUN’s 20+ years of technical accumulation in the solid control industry, the KSMR Series Trenchless Mud System has formed five core advantages through modular design and core technological innovation:

Multifunctional Integrated Design

The system integrates four functions: mud purification, circulation, storage, and mixing, and integrates the desilter and vibrating screen into one unit, significantly reducing equipment size. Taking the KSMR-200 model as an example, its total footprint requires only 5 m³, making it well-adapted to space-constrained construction scenarios and improving site utilization.

Efficient & Stable Purification Performance

According to different processing capacity requirements (200–1000 GPM), the system can flexibly configure 4–20 polyurethane cyclones. The symmetric inlet mechanism ensures uniform mud distribution, and the “wet bottom” sand discharge design effectively reduces clogging. The particle size in treated mud can be precisely controlled within 15–44 μm, guaranteeing purification stability and high efficiency.

Convenient Transportation & Maintenance

The equipment tank structure is compact, with foldable walkways and guardrails, and light weight. For example, the KSMR-200 model weighs only 5,500 kg, greatly facilitating relocation and transportation. Cyclones use clamp-type connections and screens feature soft-hook edges, which not only extend equipment service life but also simplify maintenance procedures, reducing maintenance costs and difficulty.

Low-noise & Safe Operation Experience

The vibrating screen system operates at noise levels below 85 dB, and some models are equipped with shock absorber devices to effectively reduce vibration during operation. The electrical system features explosion-proof, dust-proof, and rain-proof design, and has passed international certifications such as API, CE, and ISO14001, fully meeting safety standards for various construction projects worldwide and providing operators with a safe and comfortable working environment.

Dual Optimization of Cost & Efficiency

Through mud recycling, construction costs can be reduced by over 30%. Simultaneously, the system’s maximum daily processing capacity can reach 240 m³ (KSMR-1000 model as example), helping shorten construction schedules by 20%. It achieves dual optimization of economy and construction efficiency while ensuring construction quality.

Application Areas

With flexible processing capacity adaptability and the ability to perform in harsh environments, the KSMR Series Trenchless Mud System is widely used in core projects across multiple industries:

Trenchless Horizontal Directional Drilling (HDD)

Suitable for urban underground pipeline network installation projects, including gas pipelines, water supply pipelines, and communication pipelines. It can also be used for highway/railway crossings and river crossing projects. For example, the system has played an important role in Russian municipal pipeline installation projects and domestic long-distance pipeline construction projects.

Energy Development Field

Covers scenarios such as coalbed methane extraction, shale gas drilling, and onshore oil drilling. In an Australian coalbed methane development project, the KOSUN KSMR Series Trenchless Mud System was successfully applied, meeting high-standard drilling requirements and providing reliable equipment support for energy development.

Environmental Protection & Infrastructure Projects

In scenarios such as river dredging, sewage treatment, and auxiliary subway tunnel construction, the system achieves water resource recycling through slurry purification treatment, effectively reducing environmental pollution risks, meeting the development needs of environmental protection projects, while also providing guarantee for the smooth advancement of infrastructure projects.

Global Multi-standard Adaptation

The product has passed multiple international qualification certifications including Russian export certification, can meet construction standards in different countries and regions, and can adapt to overseas various trenchless engineering requirements, with broad application prospects in the global trenchless construction field.

Series Core Model Parameter Overview

| Model | Processing Capacity | Total Power | Applicable Scenarios |

| KSMR-200 | 200 GPM (50 m³/h) | 44 kW | Small-to-medium HDD projects, space-constrained construction |

| KSMR-500 | 500 GPM (120 m³/h) | 45 kW | Medium-to-large crossing projects, coalbed methane drilling |

| KSMR-1000 | 1000 GPM (240 m³/h) | 184 kW | Large HDD projects, high mud volume construction |

This document aims to comprehensively introduce the relevant information of KOSUN KSMR Series Trenchless Mud System, providing reference basis for engineering procurement and construction application.