highspeed oil clarification centrifuge

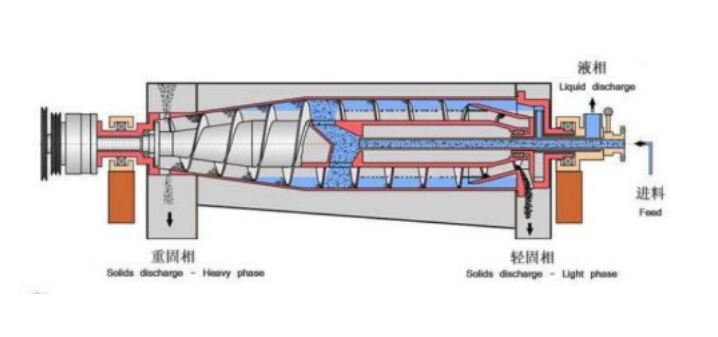

The highspeed oil clarification centrifuge represents a cutting-edge solution in industrial oil processing, designed to effectively separate contaminants from various types of oils through centrifugal force. This sophisticated equipment operates by rapidly rotating the contaminated oil, generating forces thousands of times greater than gravity, which enables the separation of particles, water, and other impurities based on their different densities. The system features advanced automated controls that maintain optimal processing conditions, ensuring consistent quality output. At its core, the centrifuge employs precision-engineered bowl assemblies and innovative disc stack technology that maximizes separation efficiency while minimizing processing time. The equipment can handle a wide range of oil types, including industrial lubricants, cooking oils, and hydraulic fluids, making it versatile for multiple industries. Its continuous operation capability allows for high-volume processing, while the sealed design prevents contamination and reduces environmental impact. The technology incorporates sophisticated monitoring systems that track performance parameters and maintain optimal separation conditions throughout the operation cycle.