hệ thống phục hồi sinh khối sinh học

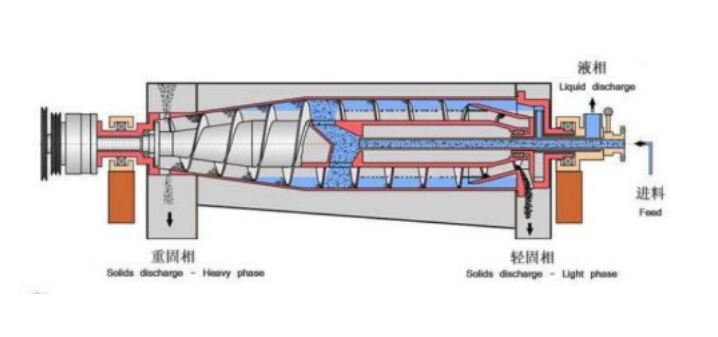

Hệ thống phục hồi sinh khối công nghệ sinh học đại diện cho một giải pháp tiên tiến trong lĩnh vực sinh học, được thiết kế để hiệu quả trích xuất và xử lý sinh khối có giá trị từ các quy trình sinh học khác nhau. Những hệ thống tinh vi này tích hợp các công nghệ phân tách hiện đại, cơ chế kiểm soát tự động và phương pháp xử lý bền vững nhằm tối đa hóa việc thu hồi tài nguyên. Các hệ thống sử dụng nhiều giai đoạn lọc, ly tâm và phân tách màng để thu hoạch hiệu quả các vật liệu tế bào, protein và các hợp chất sinh học quý giá khác từ dịch lên men và môi trường nuôi cấy. Các đặc điểm công nghệ chính bao gồm kiểm soát nhiệt độ chính xác, khả năng lấy mẫu tự động và hệ thống giám sát thời gian thực đảm bảo điều kiện thu hồi tối ưu. Các hệ thống được trang bị cảm biến thông minh liên tục phân tích các thông số quy trình, cho phép điều chỉnh ngay lập tức để duy trì hiệu suất cao nhất. Ứng dụng bao gồm sản xuất dược phẩm, sản xuất nhiên liệu sinh học, chế biến thực phẩm và đồ uống, cũng như khắc phục môi trường. Những hệ thống này hoạt động tốt trong việc xử lý nhiều loại sinh khối khác nhau, từ các nền văn hóa vi khuẩn và tảo đến vật liệu gốc thực vật, làm cho chúng trở thành công cụ linh hoạt trong các hoạt động công nghệ sinh học hiện đại. Việc tích hợp khả năng IoT cho phép giám sát và điều khiển từ xa, trong khi phân tích nâng cao giúp tối ưu hóa sản lượng thu hồi và giảm chi phí vận hành.