Nediskutabilné Očistič bahna Inspekcia a odstraňovanie problémov

Identifikácia bežných opotrebuvaní mud cleanerov

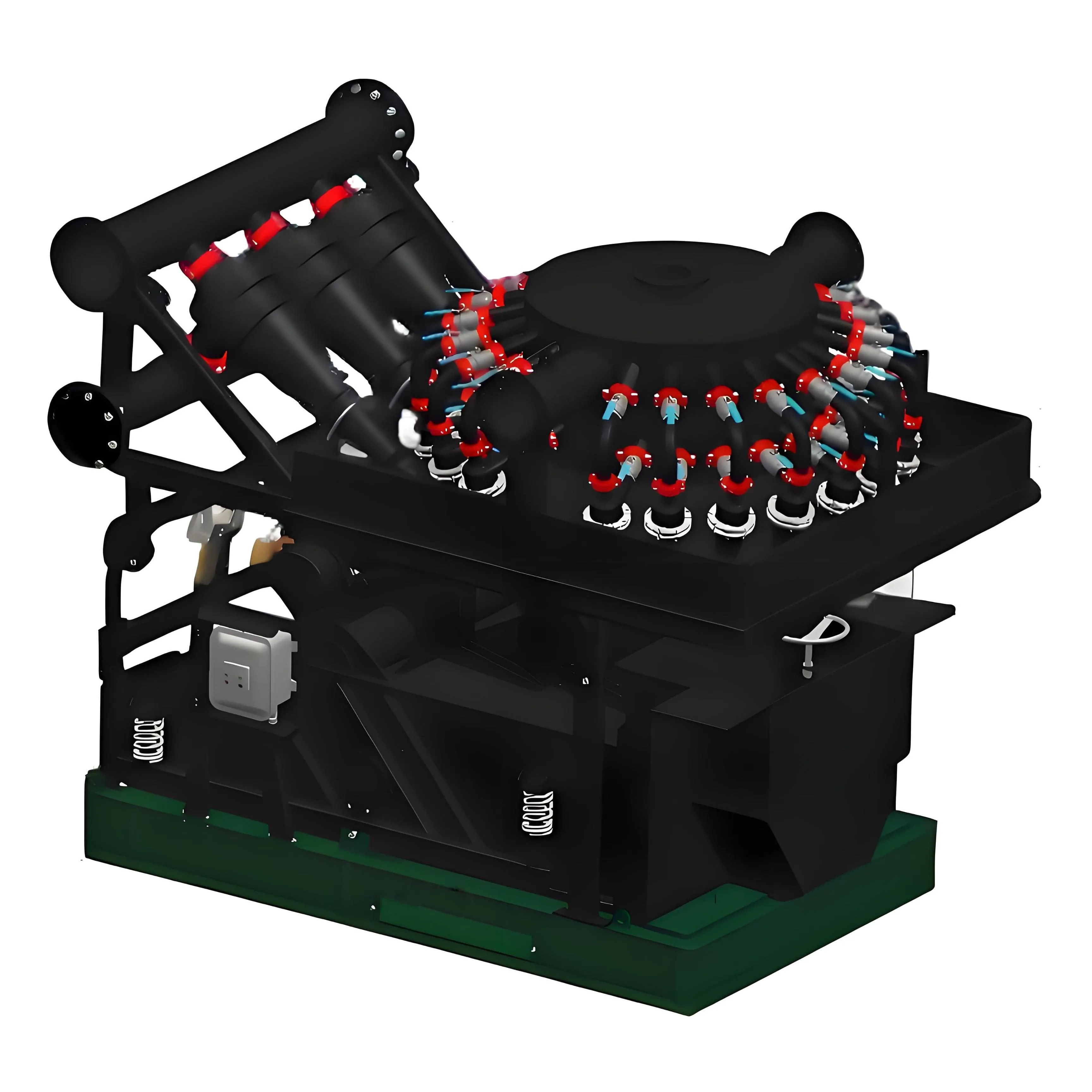

Zisťovanie opotrebovania na mud cleaneroch je veľmi dôležité, ak chceme, aby naďalej fungovali optimálne. Čo sa zvyčajne stáva? Nuž, siete sa trhajú, niekde sa objavujú úniky a súčiastky sa postupne opotrebúvajú, čo všetko narušuje správne fungovanie celého systému. Včasné odhalenie týchto problémov ušetrí peniaze na dlhú trať, pretože nikto nechce, aby neočakávané výpadky narušili prevádzku. Vezmime si napríklad poškodenie sietí – to spôsobuje, že oddelenie tuhých látok od kvapalín je menej efektívne. A keď dochádza k únikom, nielenže sa stráca cenná vŕtacia kvapalina, ale zároveň to spôsobuje väčšie environmentálne problémy.

Sledovanie týchto vzorov vyžaduje použitie rôznych nástrojov a techník. Rýchla vizuálna kontrola často okamžite odhalí poškodenie displeja, zatiaľ čo tlakové údaje z manometrov a merania prietoku pomáhajú nájsť skryté úniky, ktoré na prvý pohľad nie sú zrejmé. Pravidelné mazanie pohyblivých komponentov predtým, ako začne trenie spôsobovať problémy, výrazne predlžuje životnosť zariadení. Keď operátori včas zaznamenajú problémy a dodržiavajú pravidelné údržbové plány, zabezpečuje to dlhodobé a bezproblémové fungovanie systémov na čistenie bahna bez neočakávaných výpadkov. Úspora peňazí na náhradách samotná odôvodňuje dodatočný čas strávený prevenciou.

Ranné diagnostikovanie operačných neefektívností

Čističe bahna nerobia hladko, keď začnú neočakávane vibrávať, majú problémy s regeneráciou kvapaliny alebo spotrebujú príliš veľa energie. Keď sa tieto problémy vyskytnú, zvyčajne sa zvýšia náklady na údržbu a celková efektívnosť prevádzky zníži. Včasné rozpoznanie týchto varovných signálov je rozhodujúce pre riešenie problémov, skôr ako sa zhoršia, a pre udržiavanie vybavenia v optimálne fungujúcom stave. Po zistení problému vyžaduje zistenie skutočnej príčiny dôslednú kontrolu pomocou súčasných diagnostických prístrojov – niečo, čo každý technik v teréne vie, že je absolútne nevyhnutné, ak chceme minimalizovať výpadky.

Analyzátory vibrácií a prietokomery poskytujú obsluhe dobrý prehľad o tom, ako ich zariadenie skutočne funguje v reálnych podmienkach. Keď sa stroje začnú nadmerne vibrovať, často to znamená problémy s vyvážením niekde v systéme. A ak sa vyskytujú zvláštne kolísania prietokových rýchlostí kvapaliny, zvyčajne to znamená, že niečo upcháva potrubie alebo je niekde únik. Väčšina inžinierov na poli vám povie, že včasné odhalenie týchto problémov ušetrí veľa peňazí v budúcnosti. Oprava menších závad skôr, ako sa stanú vážnymi poruchami, zníži náklady na opravy aj straty spojené s výpadkami. Predchádzanie potrebám údržby prostredníctvom správnej diagnostiky udržiava vrtacie súpravy v lepšom prevádzkovom stave a predlžuje životnosť drahého vrtacieho zariadenia všeobecne.

Denné údržbové rutiny pre optimálny výkon čističa vrtacej sústavy

Kontroly komponentov pred spustením

Pravidelné predoperačné kontroly udržiavajú čističe bahna v najlepšom stave. Počas týchto kontrol by pracovníci mali pozorne skontrolovať čerpadlá na známky opotrebenia, skontrolovať siete na otvory alebo upchatia a zabezpečiť, aby všetky káble a spoje boli pevné a správne fungujúce. Táto pravidelná údržba zabraňuje poruchám vznikajúcim počas prevádzky, čo znamená hladší chod operácií bez prerušení. Je tiež rozumné dodržiavať smernice stanovené organizáciami, ako je API. Tieto štandardy nie sú len byrokratickou záležitosťou – v skutočnosti predlžujú životnosť zariadení medzi opravami. Väčšina technikov v teréne potvrdí, že dodržiavanie týchto špecifikácií zníži neplánované výpadky a v dlhodobom horizonte ušetrí náklady.

Protokoly odstránenia následkov po použití

Dôležitým krokom, aby naši mud cleaners dobre fungovali a vydržali dlhšie, je po každom použití odstrániť všetky zvyšky nečistôt. Tento proces v podstate znamená prejsť systém krok za krokom a odstrániť všetky nečistoty, prípadne rozobrať niektoré časti, aby sa nič počas čistenia nepreskakovalo. Ak si používatelia zanedbajú túto bežnú údržbu, postupne si všimnú, že ich stroje horšie fungujú. Mriežky sa ucpávajú, pohyblivé časti sa rýchlejšie opotrebúvajú a nakoniec vzniká predčasné poškodenie. Pri samotnom čistení väčšina obsluh zistí, že jednoduché nástroje, ako sú tuhé kefy alebo príslušenstvo k prachu na odsávanie, veľmi uľahčujú prácu v ťažko dostupných miestach. Pravidelné dodržiavanie tohto čistiacieho režimu zabezpečuje hladký chod zariadenia deň po dni a zároveň šetrí náklady na neočakávané poruchy v budúcnosti.

Čistiaci postupy a sanitácia čističiek bláta

Techniky vysokotlakového mytí pre povrchy sieťiek

Čistenie vysokým tlakom sa prejavuje ako ideálna metóda na udržiavanie čističov bahna v hladkom prevádzku, najmä na tých plochách s mriežkou, ktoré majú tendenciu zbierať všetky druhy nečistôt. Vyniká pri odstraňovaní nahromadeného prachu, bahenného kalu a zvyškov po vŕtaní, ktoré sa držia po skončení operácií. Je však dôležité vedieť, kedy a ako túto techniku použiť. Ak sa to neurobí správne, môže dôjsť k väčšiemu poškodeniu stroja. Čo robí čistenie vysokým tlakom tak cenným? Hĺbka čistenia do škár, kde sa držia tvrdohlavé zvyšky, ktoré sa nedajú odstrániť bežným šúchaním alebo jemným oplachovaním. Bezpečnosť má prioritu pri práci s akýmkoľvek tlakovým systémom. Pracovníci musia mať minimálne ochranu očí a rukavice. Tiež je dôležité držať trysku smerujúcu preč od okolostojacich ľudí, keďže vodné sústrety majú dosť veľkú silu. Preštudovanie pokynov výrobcu je tiež povinné, ak chceme zabezpečiť bezpečnosť pracovníkov aj optimálne výsledky čistenia.

Chemické čisticie riešenia na tvrdnuté nálepky

Keď vysokotlakové umývanie nestačí na odstránenie silných nánosov špiny, mud cleaner (čističe bahna) využívajú chemické čistiace prostriedky. Trh ponúka viacero možností v závislosti od toho, čo presne treba vyčistiť – napríklad odmašťovače pre olejové škvrny alebo rozpúšťadlá určené na odstraňovanie minerálnych usadenín, ktoré bežná voda nedokáže vyriešiť. Najmä však bezpečnosť! Pracovníci musia používať rukavice, ochranné okuliare, zabezpečiť dobré vetranie v pracovných priestoroch a pred zmiešaním akýchkoľvek látok dôkladne preštudovať štítky. Mnoho prevádzkovateľov uvádza, že pravidelné používanie vhodných chemických prostriedkov predlžuje životnosť zariadení bez straty výkonu. Na jednej vrtacej ploche napríklad prešli na silné rozpúšťadlo špeciálne vyvinuté na odstraňovanie oxidu železitého. Po šiestich mesiacoch nepretržitého používania sa náklady na údržbu znížili o takmer 40 % a medzičistenia sa predĺžila dvakrát. Správne zvládnutie chémie je kľúčové pre to, aby mud cleaner odolávali náročným terénnym podmienkam deň po dni.

Posudzovanie integrity vibráčnych sieť

Je dôležité kontrolovať, ako dobre odolávajú vibračné siete, ak chceme, aby naše čističe bahna fungovali správne. Väčšina operátorov pravidelne vykonáva dve základné kontroly. Najprv sa skontroluje fyzický stav samotnej siete. Skontroluje sa, či nie sú na látke trhliny, miesta, kde sa pletivo natiahlo, alebo oblasti, ktoré si časom vytvorili drobné otvory. Ďalšou otázkou je, ako dobre sieť vlastne plní svoju funkciu. To znamená sledovať, či tuhé látky prechádzajú, keď by nemali, alebo či sa rýchlosť toku nezníži nečakane. Pri rozhodovaní o výmene sietí väčšina ľudí hľadá tri hlavné známky: keď klesne účinnosť triedenia zreteľne, keď fyzické poškodenie bude príliš rozsiahle na to, aby sa dalo ignorovať, a najmä keď pletivo stále stráca svoju správnu napätosť, aj keď sa pravidelne doladí.

Je veľmi dôležité brať tieto problémy vážne, pretože keď sú displeje poškodené, výrazne to ovplyvňuje účinnosť čističov bahna. Hovoríme z vlastnej skúsenosti – ak už displej nie je v dobrom stave, celý systém začne menej efektívne oddeľovať tuhé látky. To spôsobuje rôzne problémy v ďalšom procese, kde súčiastky vykazujú rýchlejšie opotrebovanie, než by bolo normálne. Videli sme polné správy, ktoré ukazujú, že udržiavanie displejov v dobrom stave je rozhodujúce pre dlhodobú prevádzku. Výbava vydrží dlhšie, ak displeje fungujú správne, čo znamená menej výpadkov kvôli opravám a nižšie náklady na údržbu v dlhodobom horizonte.

Intervaly rekonštrukcie púpny a ventilov

Udržiavanie čerpadiel a ventilov v dobrom prevádzkovom stave prostredníctvom pravidelnej údržby a včasných rekonštrukcií zohráva rozhodujúcu úlohu pri dosahovaní najlepších výsledkov z čistiacich systémov bahna. Väčšina operátorov zisťuje, že plánovanie týchto rekonštrukcií závisí predovšetkým od počtu prevádzkových hodín zariadenia a od podmienok, ktorým bolo vystavené. Ako všeobecné pravidlo sa väčšina čerpadiel potrebuje úplnej rekonštrukcii medzi 2000 až 3000 prevádzkovými hodinami, v závislosti od zaťaženia. Ventily však vyžadujú údržbu skôr, zvyčajne okolo 1500 prevádzkových hodín, aby fungovali optimálne. Takýto preventívny prístup zabraňuje neočakávaným poruchám a zabezpečuje hladký chod celého systému bez nadbytočných odstávok.

Keď sa údržba odkladá, veci sa zhoršujú pomerne rýchlo. Zariadenie začne pracovať menej efektívne, spotrebuje viac energie, než by malo, a všeobecne sa stane otravné v práci. A pravda je taká, že keď niečo prestane fungovať, pretože si nikto nezobral čas na pravidelné kontroly, náklady na opravy môžu veľmi rýchlo narásť. Väčšina dielní už dnes tak či onak dodržiava nejaký plán pravidelnej údržby, zvyčajne zahŕňajúci mesačné kontroly a rozsiahlejšie prehliadky raz ročne, čo odporúčajú odborníci. Múdry prístup je byť vždy krok pred problémom, nie čakať, kým sa objaví. Pravidelná údržba udržiava stroje v lepšom výkone deň čo deň a zabezpečí, že vydržia výrazne dlhšie, než bude potrebné ich nahradiť.

Najlepšie postupy pre operačnú bezpečnosť a efektivitu

Štandardy naftenia pre pohyblivé časti

Zabezpečenie správneho mazania všetkých pohybujúcich sa častí na bahnových čističoch má veľký význam, ak chceme, aby tieto zariadenia hladko bežali a vydržali čo najdlhšie. Keď sa ľudia držia uznávaných smerníc pre mazanie, znižuje sa opotrebenie s časom, čo znamená lepší výkon samotných strojov. Výber mazacích látok závisí výrazne od typu zariadenia a od toho, ako sa každodenne používa. Vezmime si napríklad náročné aplikácie – tu sú najvhodnejšie husté mazivá, kde dochádza k vysokému tlaku a namáhaniu. Ľahšie oleje zvyčajne postačujú v oblastiach, kde nie je také intenzívne zaťaženie. Nedávny článok v časopise Machinery Lubrication Journal poukázal na to, že použitie nesprávnych mazacích látok spôsobuje v skutočnosti väčšie trenie a rýchlejšie opotrebenie, než sa očakáva. Takže áno, správne mazanie nie je len dobrým zvykom; je to takmer nevyhnutné na dodržiavanie priemyselných štandardov a zároveň zabezpečenie, aby tieto čistiaci systémy fungovali roky, nie mesiace.

Monitorovanie vibrácií pre dlhoväčnosť vybavenia

Sledovanie vibrácií zohráva dôležitú úlohu pri prediktívnej údržbe a pomáha predĺžiť životnosť zariadení. Keď pravidelne kontrolujeme vibrácie v čističoch bahna, vieme zachytiť problémy skôr, než sa stanú vážnymi potrebami opráv v budúcnosti. Servisné tímy dostanú včasnú výstrahu pred zvláštnymi zvukmi alebo nezvyčajnými pohybovými vzorcami, čím im umožní opraviť veci skôr, než dôjde k väčším poškodeniam, a to ušetrí čas aj peniaze v porovnaní s riešením kompletných porúch neskôr. Konferencia Machinery Failure Prevention Technology zdieľala zaujímavé údaje, ktoré ukazujú, že prevádzky so zavedenými systémami na monitorovanie vibrácií majú výrazne menej neočakávaných výpadkov. Jedna štúdia spomenula, že spoločnosti znížili náklady na opravy približne o 17 % po zavedení týchto postupov. Pre petrochemické operácie, kde výpadky znamenajú stratu príjmov, tento druh proaktívneho prístupu robí obrovský rozdiel medzi hladkým chodom operácií a nákladnými prerušeniami.

Príručka pre sezónnu údržbu a ukladanie

Opatrenia na ochranu pred studeným počasím

Zabezpečenie bezpečnosti čističov blata v mrazivom počasí znamená vykonať niekoľko rozumných krokov, aby nedošlo k poškodeniu a aby fungovali správne. Väčšina ľudí používa zmesi protimrazivých prostriedkov, aby sa zabránilo zamrznutiu tekutín vo vnútri, zatiaľ čo iní si svoje zariadenia zabaliť do špeciálnych izolačných potahov na ochranu pred krutými zimnými teplotami. Nechať zariadenie ležať nevhodne uložené? To je pozvanie na problémy, keďže zamrznuté súčiastky v lete jednoducho prestanú fungovať. Významní výrobcovia zvyčajne odporúčajú určité typy izolačných materiálov a vhodné miesta na uskladnenie ako nevyhnutné prostriedky na ochranu. Chcete znížiť problémy počas mrazivých mesiacov? Dodržiavajte základné pravidlá o udržiavaní dostatočnej teploty a pravidelne kontrolujte izolačné vrstvy, či nemajú praskliny alebo opotrebované miesta, ktoré by mohli vpustiť studený vzduch.

Dlhodobá údržba hydraulických systémov

Udržiavanie hydraulických systémov v dobrom stave počas dlhodobého skladovania vyžaduje dôkladné plánovanie, aby nedošlo k ich poruche v priebehu času. Základy zahŕňajú správne skladovanie hydraulického oleja, aby sa udržiavala správna úroveň bez kontaminácie, ako aj občasné preplachy na odstránenie nečistôt alebo usadenín, ktoré sa mohli vo vnútri systému hromadiť. Keď systém opäť začne používať po dlhšom pobyte v nečinnosti, tento druh údržby výrazne ovplyvňuje jeho následnú funkčnosť. Úspora nákladov na drahé opravy v budúcnosti výrazne závisí od správneho vykonania týchto krokov konzervácie. Väčšina výrobcov v skutočnosti poskytuje podrobné odporúčania týkajúce sa udržiavania všetkého čistého a suchého, pravidelného kontrolovania komponentov a krytia exponovaných častí ochranným materiálom, aby sa zabránilo vplyvu prachu a vlhkosti. Osoby, ktoré týmto odporúčaniam budú nasledovať, zistia, že ich hydraulické zariadenie po skladovaní znovu bezproblémovo funguje.

Často kladené otázky

Aké sú bežné obnovené vzory v čističoch bahna?

Bežné štipy poškodenia zahŕňajú trhliny na obrazovke, úniky a mechanické poškodenie. Ich časná detekcia pomáha predchádzať nákladným simplym práce.

Ako môžu byť diagnostikované operačné neefektívnosti v čističkách blát?

Operačné neefektívnosti je možné diagnostikovať pomocou nástrojov ako sú analizátory vibrácií a meracie prístroje pre prietok. Tieto nástroje pomáhajú identifikovať problémy ako sú mechanické nesprávne zarovnanie a zatkanie.

Aká je dôležitosť kontrolných skúšaní pred spustením?

Kontrolné skúšanie pred spustením prevencia neočakávaných porúch a zabezpečuje, že čističe blát sú v najlepšom stave, čo zvyšuje spoľahlivosť a minimalizuje simply.

Ako často by mali byť rekonštrukované pumpy a ventilky?

Pumpy by mali byť rekonštrukované každé 2000-3000 hodín operácie, zatiaľ čo ventily by mali byť skontrolované každé 1500 hodín, aby sa udržala efektívnosť.

Aké opatrenia je potrebné podniknúť na ochranu čističiek blát pred studeným počasím?

Na ochranu pred mrazivými teplotami a zabezpečenie optimálnej funkčnosti by mali byť použité protimrazné riešenia a techniky izolácie.

Obsah

- Nediskutabilné Očistič bahna Inspekcia a odstraňovanie problémov

- Denné údržbové rutiny pre optimálny výkon čističa vrtacej sústavy

- Čistiaci postupy a sanitácia čističiek bláta

- Najlepšie postupy pre operačnú bezpečnosť a efektivitu

- Príručka pre sezónnu údržbu a ukladanie

-

Často kladené otázky

- Aké sú bežné obnovené vzory v čističoch bahna?

- Ako môžu byť diagnostikované operačné neefektívnosti v čističkách blát?

- Aká je dôležitosť kontrolných skúšaní pred spustením?

- Ako často by mali byť rekonštrukované pumpy a ventilky?

- Aké opatrenia je potrebné podniknúť na ochranu čističiek blát pred studeným počasím?